- HOME

- Our Commitment to Manufacturing

Our Commitment to Manufacturing

Introduction

1. Our commitment to realizing safety and security through thorough quality management

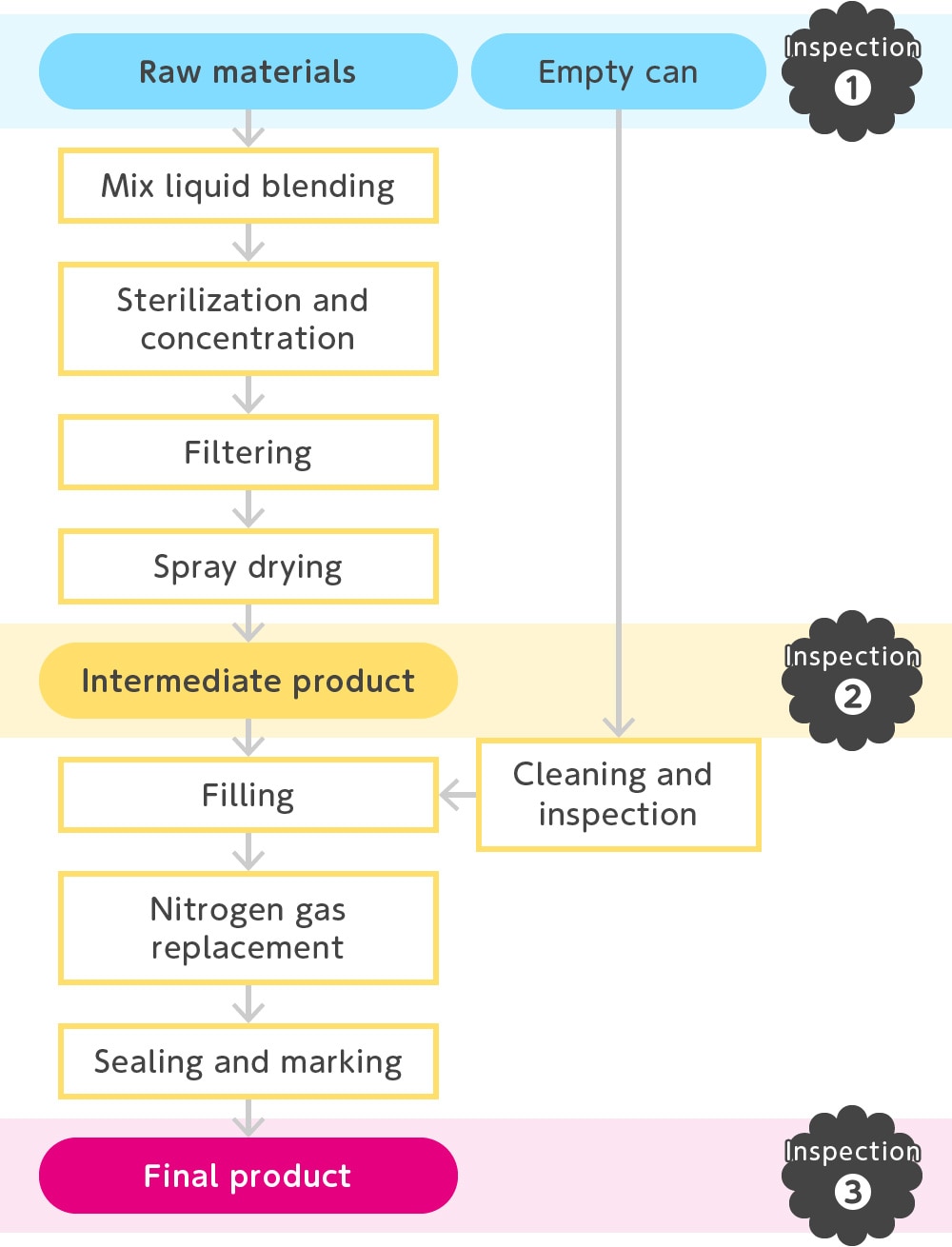

Inspections are carried out 3 times: for raw materials, intermediate products, and before shipping (for final products)

Powdered milk product is carry out based on an FSSC22000 management system with all processes being strictly managed through a system which incorporates the HACCP* hygiene management procedures. In addition, rigorous inspections are carried out at 3 stages during production: inspection of raw materials, inspection of intermediate products before filling in cans, and inspection of final products before shipping.

Example: <Final product inspection>

(1) Check for 6 types of microorganism including coliform bacterium

(2) Sensory inspection

(3) Solubility check, foreign matter check

(4) Individual inspections by product group (ingredients, etc.)

(5) Measurement of radioactive material

Only products which have passed all of these inspections are shipped.

2. Careful raw material procurement

Raw materials are jointly checked by the Development Department, Production Department, and Quality Management Department

Only materials which have been verified to be safe and meaningful for infants

Only materials which fulfill our strict, unique standards are used

We do not build "stocks" of raw ingredients

3. Thorough production control using strict standards

Work processes

1. Mix liquid blending

The various raw materials which will become the base for the powdered milk are mixed together.

2. Sterilization and concentration

The mix liquid is heated to sterilize it, and then water content is evaporated to bring it to a specific concentration.

3. Filtering

Impurities are removed by passing the mix liquid through specialized filters.

4. Spray drying

The mix liquid is sprayed suspended in air using specialized machinery to rapidly cool and dry it into a powder.

5. Filling

The powdered milk is filled into cans.

6. Nitrogen gas replacement

When the powdered milk is added to the cans, the air in the cans is suctioned out and replaced with nitrogen gas to prevent the powdered milk from oxidizing and deteriorating in quality.

7. Sealing and marking

The product is completely sealed in the cans, and the production date and other information is printed on the bottoms of the cans.

MEGMILK SNOW BRAND Quality

LANGUAGE

LANGUAGE